- Hyderabad, Telangana

- +91-9133388349

- info@aacorp.in

- Youtube

- Get In Touch

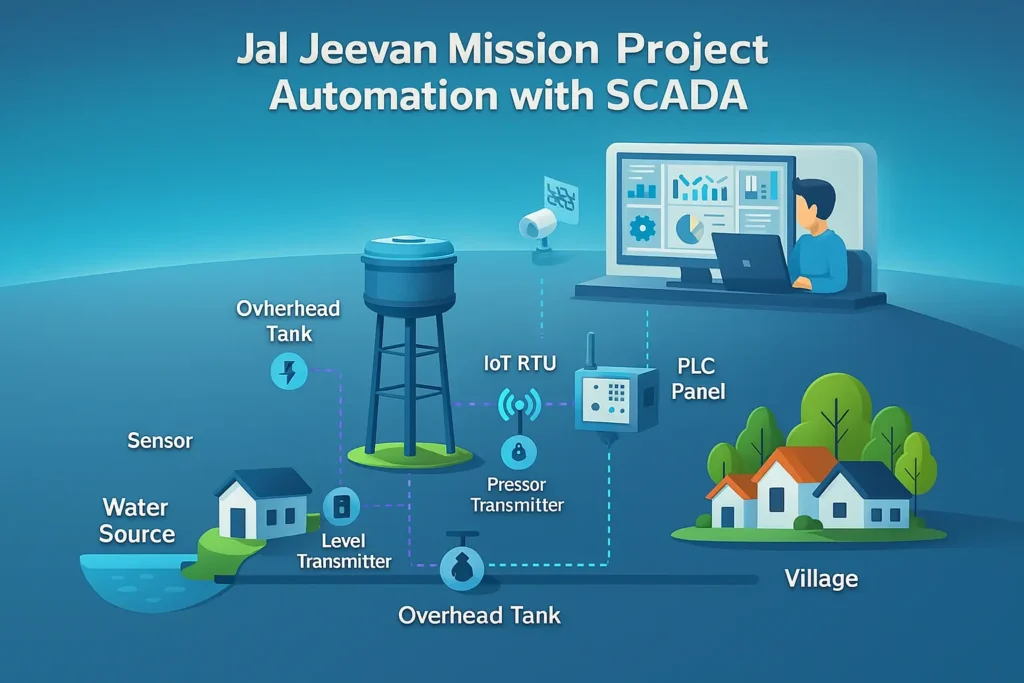

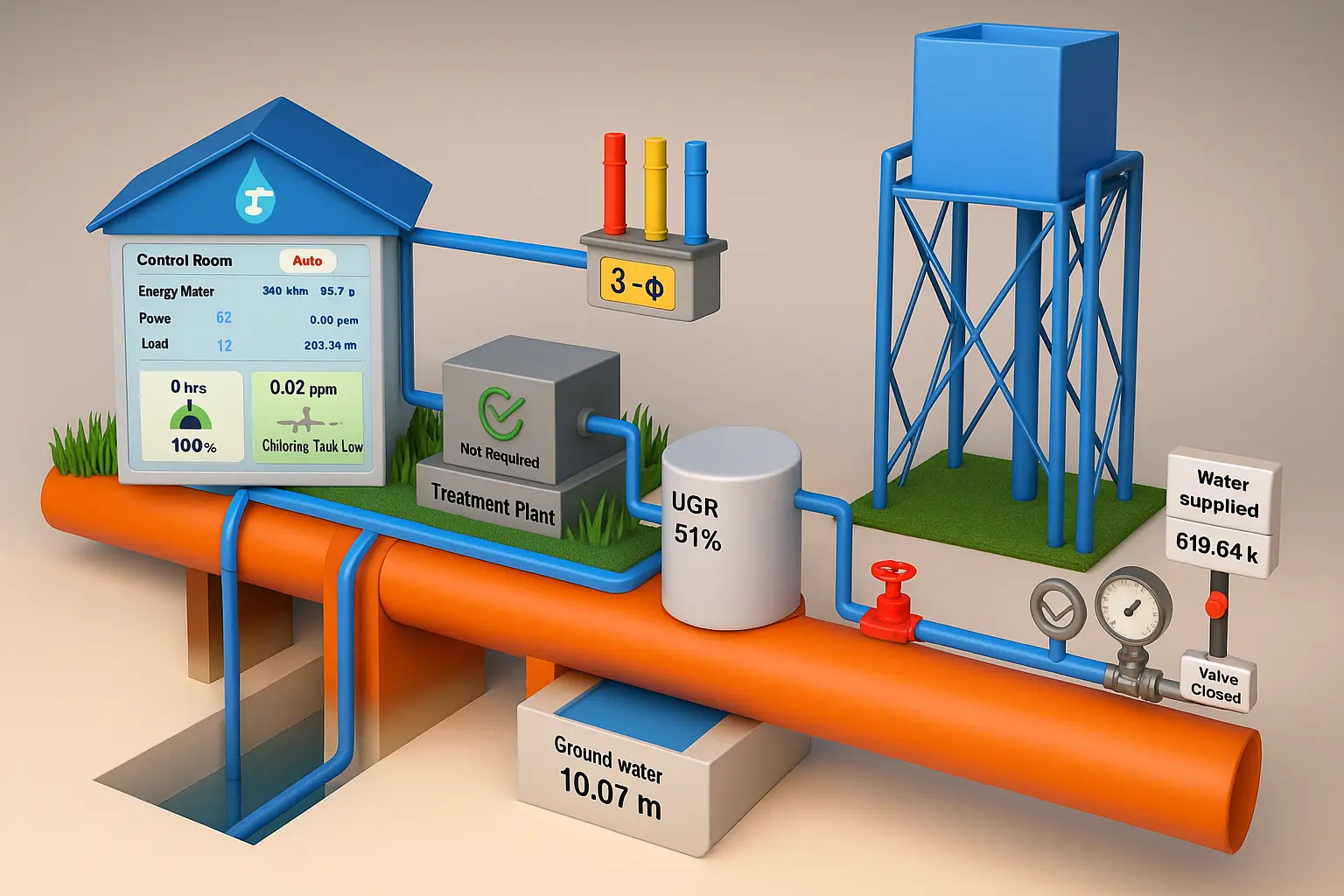

To achieve the Government of India’s 24×7 safe drinking water vision, We integrates SCADA systems across all project components. The platform automates pump operations, monitors energy, measures flow/pressure, and ensures consistent water quality — all through a centralized, cyber‑secure control center.

Reliable local control and remote telemetry.

Unified view via cloud & on‑prem.

Track flow, pressure, level, energy.

Fault detection & energy anomalies.

Trends, historian, reports.Data

24×7 live feed & storage data.

MFM-based tracking & scheduling.

Encryption & role-based access.

Remote terminals at OHT / MBR / IPS sites allow operators to manage pumps, view alarms, acknowledge faults, and generate performance reports — ensuring unified control from any location.

Trends, historian, reports.Data

Large 2m × 1m engraved mimic panel showing live water network, valves, and pump indicators.

Priority-based alarm display for electrical, hydraulic, and quality faults with acknowledgment control.

Generates daily, weekly, and monthly reports on water balance, efficiency, and quality compliance.

AI-based insights for pump optimization, NRW reduction, and chemical dosing control.

100+ JJM Sites

99.5%

Auto-generated

20–25%

All layers

Improved KPIs

Provide Faster Delivery

Best Service with 100% Satisfaction

Anytime & anywhere you’re.

Low Prices and Discount offers

© Copyright 2025 – All Rights Reserved By A&A Corporation